FlatBed Mulitpass FJET

UV Flatbed printers are also known as scanning printers, because the printheads move back and forth while building the specified resolution across the object to be printed.

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Meet the Series

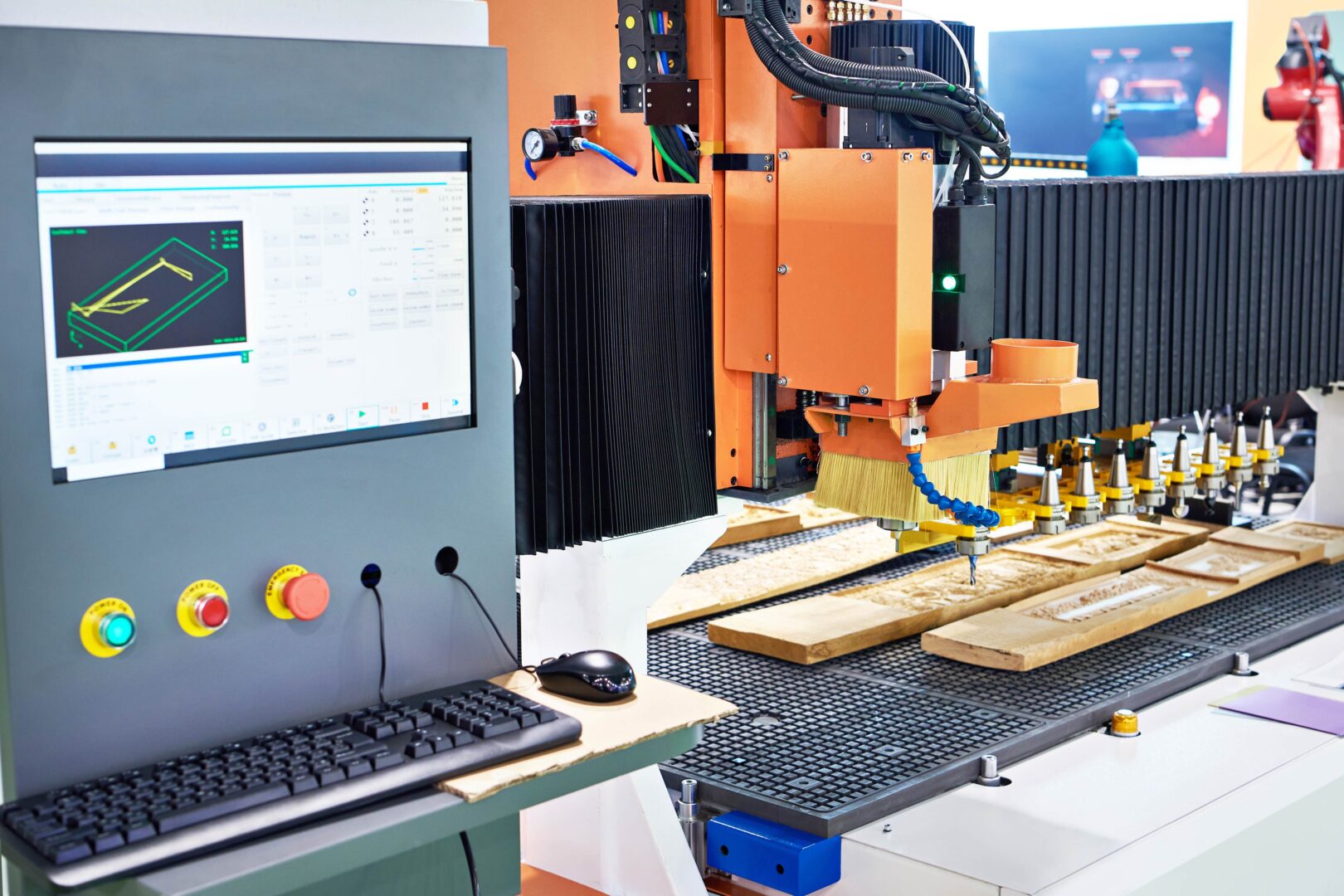

UV-LED Curable Flatbed Inkjet Printers

Print a full platen of parts, each with its own design. It’s easy with industrial flatbed UV-LED printers. Because they are digital, there are no plates to etch, and art can be stored for future use. With CMYKWW or a varnish option, these uv flatbed printers can print a full platen in about a minute depending on resolution and configuration, producing vivid, memorable designs at up to 1200 x 1200 dpi.

Features

Precision engineering meets custom flexibility

Our UV-LED curable flatbed inkjet printers are best for flat or semi-flat materials. In flatbed UV printers, color is built up by repeated passes over the object. With a large platen, many parts can be printed on one printer at the same time, all with the same or different images. Variable-data printing is also available, enabling batch-coding or mass-customization. Our flatbed inkjet printers produce sharp images with smooth gradients up to 1200 x 1200 dpi.

See it in Action

Explore real-world use cases across materials, shapes, and production requirements—and discover how EPS technology delivers consistency, quality, and durability for complex applications.

Models in this Series

Model Specifications

|

Model |

Lorem Ipsum Specification |

Lorem Ipsum Specification |

Lorem Ipsum Specification |

|---|---|---|---|

|

XD-70 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-180 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-140 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-360° |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

Related Equipment & Supplies

EPS supplies more than just equipment. We provide essential accessories and consumables that can be purchased with your printer or after installation to support ongoing production and evolving needs. Contact our Customer Service Team for support!

Accessories

Adjustable Base Fixture

Bowl Feeders

BR35M

BR50M

BR50SV

Centrifugal Feeder

Digital Printer Consumables

PLT-FJW Digital Ink

PLTFJ-LFC, Gen 4, Flexible, UV Curable FJet Printing Ink

PLTIJ-HAD, Hi-Adhesion UV cure ink

PLTIJX Digital Printing Ink

PLTMD Digital Printing LED Curable Ink

PLTUV20 Digital Printing Ink

product Support

Frequently Asked Questions

Have questions you’re looking to get answers to? Our team of experts is here to ensure your success!