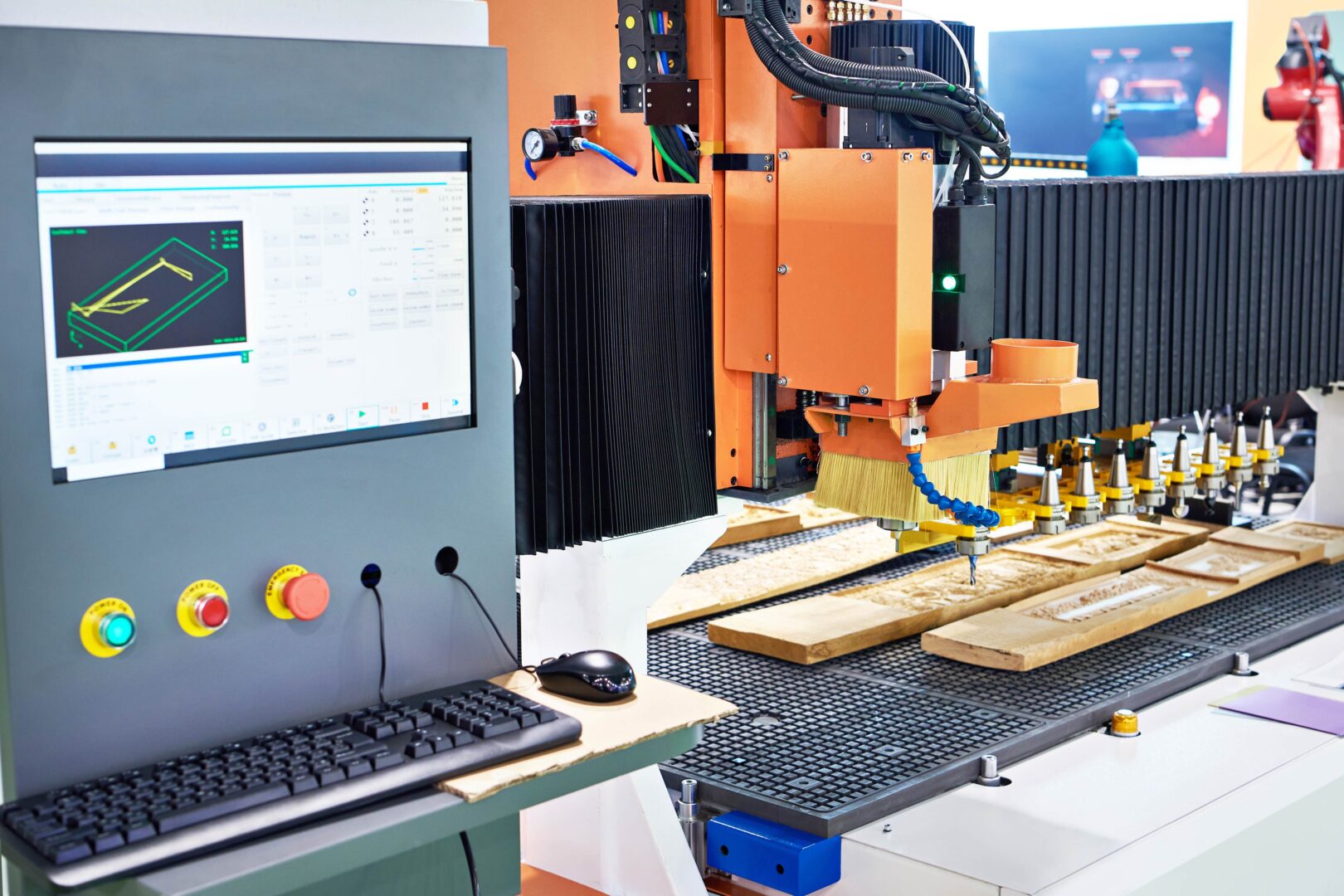

XD1 Linear Automated Single Pass Inkjet Platform

High-Speed automated single pass technology built for scale based on print swath and print heads.

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Lorem Ipsum Dolor Sit Amet

Meet the Series

Engineered for high-throughput, industrial-scale production

The XD Linear Series prints “image direct” from computer to print. It is the perfect solution for short or long runs with quick changeovers and variable data. This inkjet printer is ideal for multi-color printing on flat and semi-flat surfaces on a variety of substrates and can be customized to meet your printing needs.

Features

Precision engineering meets custom flexibility

The core of the XD Liner series is the printing cell. The XD series offers print widths of 70, 108, 140, and 210mm. Every industrial inkjet printer in the XD series consists of inline pretreatment, a linear conveyor, and inline UV curing.

Typical head configurations in our singlepass inkjet printers consist of WW + CYMK. It is also possible to vastly expand the color gamut with the addition of print heads inkjetting Orange, Green, and Violet.The core of the XD Liner series is the printing cell. The XD series offers print widths of 70, 108, 140, and 210mm. Every industrial inkjet printer in the XD series consists of inline pretreatment, a linear conveyor, and inline UV curing.

Typical head configurations in our singlepass inkjet printers consist of WW + CYMK. It is also possible to vastly expand the color gamut with the addition of print heads inkjetting Orange, Green, and Violet.

See it in Action

Explore real-world use cases across materials, shapes, and production requirements—and discover how EPS technology delivers consistency, quality, and durability for complex applications.

Models in this Series

Model Specifications

|

Model |

Lorem Ipsum Specification |

Lorem Ipsum Specification |

Lorem Ipsum Specification |

|---|---|---|---|

|

XD-70 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-180 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-140 |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

|

XD-360° |

Lorem Ipsum |

Lorem Ipsum |

Lorem Ipsum |

Related Equipment & Supplies

EPS supplies more than just equipment. We provide essential accessories and consumables that can be purchased with your printer or after installation to support ongoing production and evolving needs. Contact our Customer Service Team for support!

Accessories

Adjustable Base Fixture

Bowl Feeders

BR35M

BR50M

BR50SV

Centrifugal Feeder

Digital Printer Consumables

PLT-FJW Digital Ink

PLTFJ-LFC, Gen 4, Flexible, UV Curable FJet Printing Ink

PLTIJ-HAD, Hi-Adhesion UV cure ink

PLTIJX Digital Printing Ink

PLTMD Digital Printing LED Curable Ink

PLTUV20 Digital Printing Ink

product Support

Frequently Asked Questions

Have questions you’re looking to get answers to? Our team of experts is here to ensure your success!